The youtube video used to have captions to describe the meaning

of all the menu settings. However, the captions have disappeared

for unknown reason. I've now gathered operating instructions here.

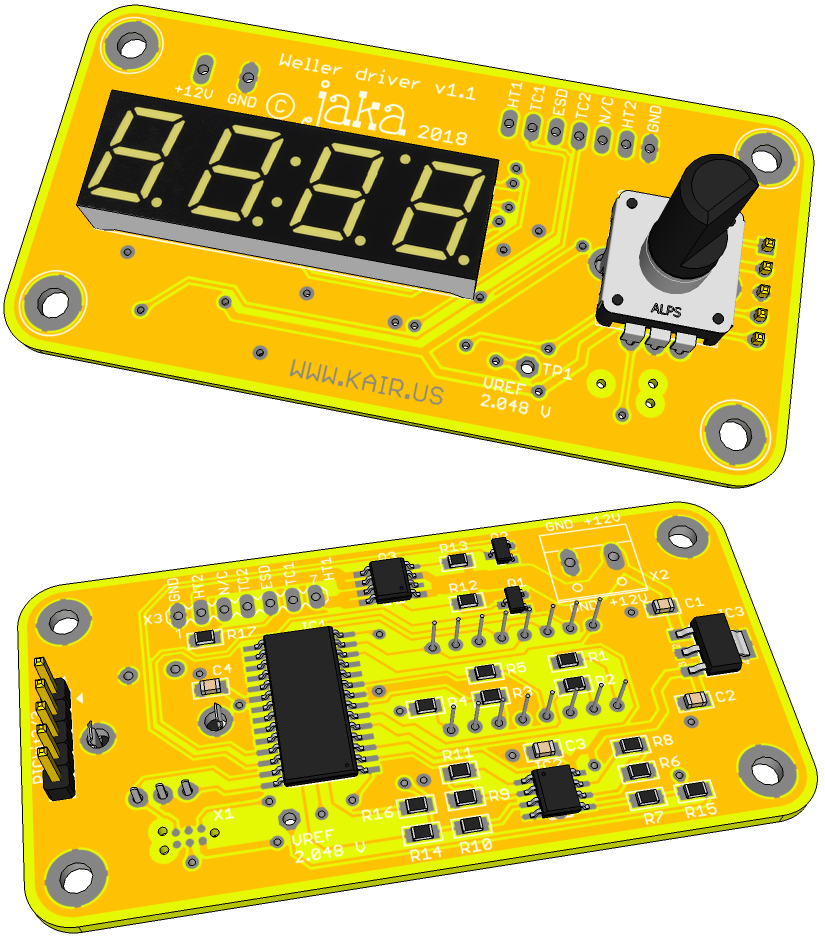

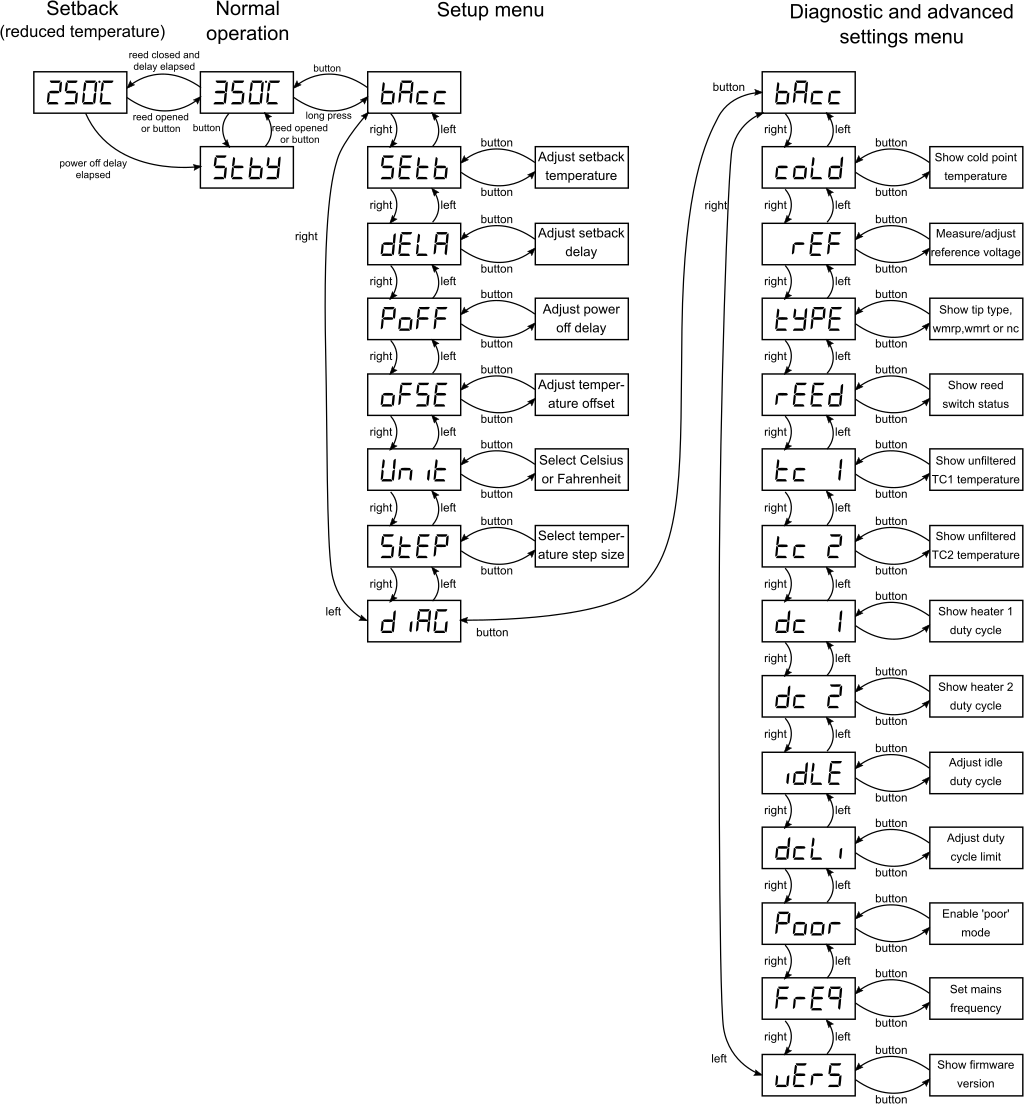

You can also refer to the menu state diagram further below to help

navigation in the menus.

The basic usage of the soldering station is very simple. When you power it up, it heats up to previously used temperature. You can change the temperature by rotating the knob. The station can be put to standby by pressing the knob.

There is setback mode as in original Weller station. It means

that temperature is reduced to a lower value to preserve tip life

if the station is not used for a while. There is a reed switch on

the handle and a magnet in the stand. When the iron is on the

stand for a predefined time, it goes to reduced setback

temperature. You can revert back to normal operating temperature

by taking the iron from stand or pressing the knob.

If the station is unused for a longer period, it goes into

standby mode. In standby mode the heating is completely off.

Normal operation can be resumed by taking the iron from the stand

or pressing the knob.

Basic setup parameters can be adjusted in setup menu. These parameters have all similar function as the genuine Weller setup parameters. You can enter the setup menu by a long press of the knob, approximately one second.

'bAcc' or Back exits the setup menu and resumes normal

operation

'SEtb' or Setback allows to set the setback temperature.

Default value is 250ºC.

'dELA' or Delay sets the setback time delay in minutes. You

can also set the delay to zero, then the iron goes immediately to

standby when put to stand. You can also disable the setback

feature by turning the delay setting to maximum 'oFF'. Default

value is 5 minutes.

'PoFF' or Power off delay sets power off delay in minutes.

Also this setting can be set to zero or off. However it is not

recommended to set to zero because repeated cooling down and

heating up just puts more stress to the heating element. Default

value is 30 minutes.

'oFSE' or Offset allows to fine tune the iron temperature.

If you have a soldering iron temperature meter or the Weller

calibration tip, you can correct the temperature offset here. If

you don't have any means to measure actual iron temperature, leave

this setting to the default value of 0ºC.

'Unit' sets temperature display unit, either Celsius or

Fahrenheit. Default is Celsius.

'StEP' sets temperature adjustment step size. It can be set

to 1ºC or 5ºC. When in Fahrenheit, the coarse step is 9ºC.

'diAG' or Diagnostics enters the diagnostics and advanced

settings menu level

The diagnostics and advanced settings menu contains diagnostics

information which can be helpful in debugging your newly built

soldering station. It also contains some advanced settings which

are not available in genuine Weller stations.

'bAcc' exits the diagnostics menu and returns to setup

menu

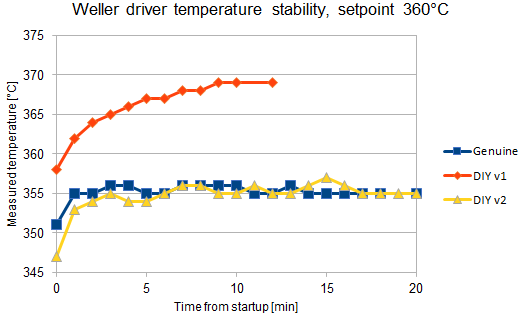

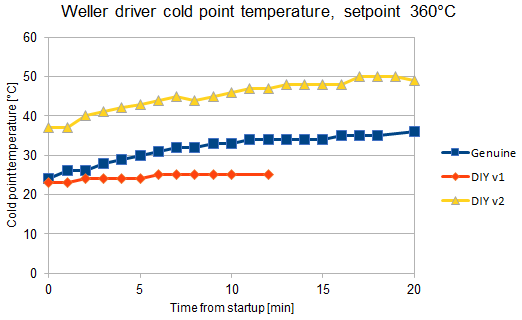

'coLd' shows the cold point compensation temperature. This

is the temperature measured from inside the iron handle, close to

the 3.5 mm jack. This temperature should be close to room

temperature if you have just the handle connected without the tip

(and handle is otherwise cool, that is, not used for some time).

This temperature will rise during normal use, maybe up to 50ºC,

depending on handle type, target tip temperature and ambient

temperature. If the temperature sensor is not connected (e.g.

'poor' mode is enabled), the cold point temperature defaults to

30ºC.

'rEF' allows to fine tune the PIC16F1788 internal voltage

reference. The internal reference can have initial tolerance of up

to ±5%, although I haven't ever seen nowhere near that big errors.

When you enter this menu setting, the reference voltage is

constantly on. You can use a multimeter to measure the reference

voltage from the test point on the Weller driver PCB. Then enter

the measured voltage to this menu setting. The temperature

calculations will then take the reference error into account. Note

that the reference voltage is available on the test point only

when this menu setting is active.

'tyPE' shows the connected tip type which the Weller driver

has identified. Shows 'WMrP' for the soldering pen, 'WMrt' for the

soldering tweezers and 'nc' if nothing is connected. The tip type

is recognized based on the size of resistor in parallel with the

reed switch inside the handle. If the iron is on stand when

powering up, the resistance can't be measured because the reed

switch is shorting the resistor. In this case, the tip type is

recognized by briefly pulsing current to heater 2, and tip type is

recognized based on the response.

'tc 1' and 'tc 2' show unfiltered thermocouple

temperatures. Thermocouple 1 is the WMRP thermocouple or WMRT

right tweezer temperature. Thermocouple 2 is the WMRT left tweezer

temperature.

'dc 1' and 'dc 2' show duty cycles of heating

elements. Duty cycle 1 means again WMRP or WMRT right tweezer

heater duty cycle. Duty cycle 2 is WMRT left tweezer.

'idLE' allows to set a duty cycle value below which is

considered as 'idle'. This is an alternative way of detecting that

the iron is not used. You can use this e.g. if you don't have the

magnet on stand or the reed switch on the handle. If the duty

cycle is below the value set here for duration of setback delay,

it goes to setback temperature. It also further goes into standby

if the duty cycle still stays below this setting for the duration

of power off delay. The station will also revert back to normal

temperature from the setback temperature if the duty cycle

increases higher than this setting. However, if the setback

temperature is very low, it might not be possible to get high

enough duty cycle for resuming. Also from standby you need to

return to normal operation by pressing the knob, since there the

duty cycle will always be 0 because heater is off. You can look at

typical duty cycles in 'dc 1' menu during soldering and inactivity

to help selecting a suitable setting here. If the components you

are soldering are very small, this method probably doesn't work

since the duty cycle is small all the time. You can set this

setting to 0 or 'oFF' to disable this feature, which is the

default setting.

'dCLi' sets a maximum duty cycle for the heaters. Setting a

higher value gives you faster heat-up time and more heating power,

but downside is reduced heating element life. A smaller value

might increase the heater element life but heating is slower and

soldering of large parts becomes more difficult. The default duty

cycle is 58% for 50 Hz mains setting and 50% for 60 Hz mains

setting. When the supply voltage to Weller driver is 12.0 V, the

58% duty cycle gives very similar heat-up speed as the genuine

Weller WD1M, WD2M and WR3M stations. It is highly recommended to

leave this setting to default value. However, if you need more

power to solder something big and heavy, you can briefly increase

this setting at your own risk.

'Poor' allows to enable or disable 'poor mode'. This mode

allows to use a poor mans handle, i.e. just the 3,5 mm stereo

jack. When enabled, the station assumes that a WMRP is always

connected, reed switch is closed and cold point temperature is

30ºC. Despite the name of this mode, it actually works really well

and is completely adequate for hobby users. See more info from

Q&A section on how to connect the 3,5 mm stereo jack in this

mode. The default setting is poor mode off.

'FrEq' sets the mains power frequency. Set this to either

50 Hz or 60 Hz, whichever is used in your country. This setting

affects the temperature measurement timing and filtering. I have

noticed that mains frequency noise coupling to iron cable is the

most common cause for unstable temperature readings from the tip.

The thermocouple produces a tiny, millivolt level voltage which

can be easily ruined by noise coupled to signal. The mains

frequency can be very effectively eliminated by sampling the

temperature at twice the mains frequency, and averaging two

consecutive measurements. It doesn't matter that the sampling is

not actually synced to mains frequency, as the two measurements

will cancel out the error, assuming that it has sinusoidal or

otherwise symmetric shape (which it usually has). Default setting

is 50 Hz.

'vErS' shows the firmware version.

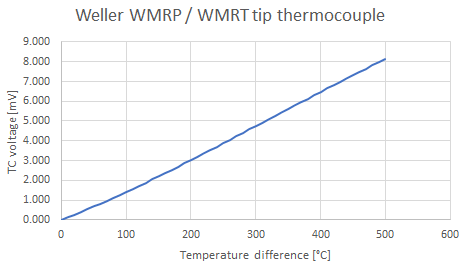

The thermocouple inside the WMRT and WMRP tips seems to be quite

close to D-type thermocouple. On firmware versions up to 0.901 I

was using lookup table based on D-type thermocouple. On newer

firmwares the lookup table is calibrated using Weller K1101

calibration tip. Calibrated TC voltage vs. temperature is shown in

graph below. You can download the data

in excel format from here.

Q: How to connect WMRP / RT tip with 3,5 mm stereo jack?

A: See WMRP pinout from here.

Connect sleeve to 'GND'. Connect ring to 'TC1'. Connect tip to

'HT1'. Use FW v0.6 or newer, enable 'poor' mode from diag menu.

Q: The WMRT tip makes noise! Is this normal?

A: It seems that the heating elements of WMRT make noise when

power is switched on or off rapidly. Earlier firmware versions

used to periodically pulse current to heating element 2 to

recognize tip type. This caused constant buzz with WMRT even when

in standby. FW 0.6 and newer recognizes tip type from resistor in

parallel with reed switch so the noise is reduced. Original Weller

stations drive heating elements using AC and zero point switching.

So the current to tip rises and falls slowly, that's why they

don't make noise.

Q: The temperature reading is not stable like in the Youtube

video, it flickers like there's noise in temperature readout.

Why's that?

A: Most likely some external disturbance is coupled to the iron

cable. The output of the thermocouple is only some millivolts so

it is quite sensitive. WMRT is more sensitive because it has 2k

resistor in series with thermocouple while WMRP has 1k. Especially

mains frequency seems to couple to the thermocouple line. Starting

from firmware v0.6 there is special filtering against mains

frequency noise. Temperature measurements are done at double the

mains frequency interval, and two consecutive measurements are

averaged. This effectively cancels any mains frequency noise. The

diagnostics menu has a setting to select between 50 Hz and 60 Hz

mains frequency, be sure to set it correctly. Another thing which

may help is to connect the ground of the soldering station to

mains ground. The noise might also originate from your power

supply, so you can try to add capacitors at Weller driver supply

voltage input or try different type of power supply.

Q: How can I program the PIC? There is nothing on the PCB to

connect the programmer!

A: See this page for more

information on how to program the PIC in my projects.

Q: I have read and understood the PIC programming instructions

but I still can't program it. The programmer doesn't find the PIC!

A: The ICSP lines on this board are shared with the rotary

encoder. On some encoders, the encoder can keep the one of the

programming lines pulled down even when it is at detent position,

where both switches should be open. Try to rotate the encoder to

such position that neither PGD nor PGC are pulled to GND.

Q: I can only adjust the reference to one direction! Some of the

parameters show '-1' or other erroneous or garbage values!

A: These kind of issues seem to happen if the PIC is programmed

with MPLAB IPE. By default, the MPLAB IPE doesn't seem to erase or

program the data EEPROM. These kind of problems are fixed in

firmware v0.9 and newer. All the parameters are checked at startup

and if any of those are outside of valid range, all parameters are

set to default values.

Q: Can I use the (rare) 24V version of the WMRP tip or WMRT

tweezers with this station?

A: Yes, it is possible. The voltage regulator IC3 needs to

withstand 24V. You should use e.g. UA78M05CDCYR type given in BOM

as alternative type. This has been tested to work.

kair.us/ projects/ weller_driver/

page created 23.12.2015