This is the fourth, and maybe the final version of my digital

wall clocks. I wanted to to retain all good features of version 3

and add some new. I also targeted to lower the cost of parts, as

the Maxim DS3231 is very expensive and the SAA1064 display drivers

were not too cheap either. So the LED drivers are replaced with

TLC5925, and RTC is changed to PCF2129. On circuit design the swap

of these parts was quick, but on FW side a little slower, as I had

to write the drivers.

You can see a presentation of the features on this video. The video

also compares the previous clock versions briefly.

The version 4 uses same 58 mm (2.3") displays as version 3. There are compatible displays available from several manufacturers. The displays must be common anode type. Suitable displays are e.g. Sharlight CM1-2302 series, Kingbright SA23-11 series, Wenrun LSD230B series and also most of the 2.3" displays from eBay.

The best matching flat top LED for the cheap eBay displays that

I've found is Kingbright WP483SRSGW (or older code Kingbright

L-483SRSGW). This is actually bi-color LED but when mounted as in

assembly drawing, it lights red. When mounted the other way round,

it will light green. The green is a good match for Wenrun

LSD230BAG-101-01 green display which is available from TME at a

very affordable price. The picture on top of this page shows the

green Wenrun display. I've also used shrink tube around the LEDs

to prevent light leakage from side.

Previous clock used the internal temperature sensor of the DS3231

RTC to show temperature. This wasn't however giving accurate

readings since the power dissipated by displays and drivers was

heating the RTC. Version 4 has connectors to fit two external NTC

thermistors to measure inside and outside temperatures. Suitable

thermistors are available from eBay. They have 10 kohm

resistance beta value of 3950. The thermistors have an XH

connector at one end, which is a Chinese copy of JST

XH series connector. You can use either the genuine JST or

the Chinese replica on the PCB. According to my measurements these

thermistors follow very closely to this

chart on Adafruit website. I measured one thermistor in ice

water 31.87 kohm and in boiling water 652 ohm. The firmware has an

array based on the Adafruit table and in practice the displayed

temperature value seems to follow very closely to a commercial

digital thermometer.

The remote control support is improved. The firmware supports

Nec, Nec42, Samsung, SIRC, Kaseikyo, Matsushita, JVC and RC-5

protocols. It also has a learn function which can be used to teach

it to work with any remote which uses one of the supported

protocols. You can use e.g. an old TV or DVD remote control to

control the clock. The IR receiver should be chosen based on the

carrier frequency used by the protocol. SIRC uses 40 kHz, RC-5

uses 36 kHz and the rest use 38 kHz. However, the 38 kHz works

quite well also for SIRC and RC-5. An example of suitable 38 kHz

receiver is Vishay TSOP53438. It is cheap, sensitive and has good

noise rejection.

Time base of the clock is derived from PCF2129AT. It also

provides battery back-up. The power consumption of the RTC is 2.15

µA when in backup mode. A CR2032 battery has a typical capacity of

190 mA so it should last for over 10 years. Of course when clock

is getting power, the battery is not drained. The PCF2129AT is

temperature stabilized and the accuracy is very similar to DS3231

for only fraction of price.

A piezoelectric buzzer can be used to give audible alerts.

Currently there is possibility to configure it to hourly beep

and/or wake-up alarm. There is also an IR emitter LED which is

used in master / slave setup to transmit time and date from master

clock to slaves. It could also be used for alarm, so the clock

would e.g. turn on TV when the alarm activates, but this is not

currently supported.

There is also a footprint for U-blox CAM-M8 GPS / Glonass /

Galileo / BeiDou module. The firmware has automatic recognition

for GPS module and PCF2129 RTC. It works with eiher one, or both.

The firmware only uses the time and date from GPS, derived from

GPRMC message.

The schematics are pretty straight forward. The PIC16F1788

firmware makes most job.

Input voltage is fed to connector X1. It should be high enough to

be able to drive the chain of 4 LEDs in each segment. For red

displays this is typically around 7.5 V. Then the output stage of

TLC5925 needs an additional 1.0 V to maintain regulation. A 12 V

power supply is OK for most display types. To save some power, 9 V

supply is usually also OK. Voltages up to 17 V can be used (or up

to 16 V if using MCP1703-3302E/DB as regulator IC6), but this

causes just more power wasted and heat generated in the display

drivers. Diode D1 protects from incorrect supply polarity, but for

over voltage there is no protection.

The displays are driven by three TLC5925 constant current LED

drivers. They are controlled via SPI bus from PIC. The LED current

is set with a resistor in R-EXT pin on the TLC5925. Current at

each output is 18 times the R-EXT pin current. Now a little trick

is used to allow global brightness control of all segments. The

integrated DAC and integrated op-amp of PIC is used to control the

low sides of R-EXT resistors. This allows easy brightness control

without using PWM and without all the disadvantages associated

with PWM.

GPS module CAM-M8 is configured to use it's internal antenna, so

the only external component it needs is a bypass capacitor. It is

connected to the PIC via UART. Main purpose of the module on this

clock is to provide automatic and accurate time setting.

kello_v41.sch.pdf

11.9.2018 Circuit diagram v4.1

The PCB for the clock is designed using Cadsoft Eagle version

5.12. The design is double sided, and design rules are quite

relaxed. Most of the components are SMD and on bottom side of

board. Only the parts which need to be visible or are too high for

bottom side are on top. This minimizes board area since the

displays fill up the top side of board almost completely. Segment

order for display drivers is same as in previous version. It

allows simple routing of all segment signals in one layer. This

causes some more work in display driver source code, since the

segment order is different for the two displays controlled by one

chip.

You can order the boards from PCBWay from here.

When ordering, choose black solder mask. It makes the board less

visible and the clock looks very sleek if you use smoke tinted

plexiglass over it. Note that I haven't ordered the v4.1 boards

from PCBWay myself, I ordered those from another factory so I know

that the Gerber files should be OK. Please let me know if you

order the boards from PCBWay, so I can update info here to confirm

it works OK.

Note when ordering parts; you can save costs by leaving out

functions you don't need. Many of the parts can just be left out

without affecting other features of the clock. The GPS module is

the most expensive component and it doesn't bring that much

advantage because the PCF2129 is very accurate. On the other hand,

if you use GPS, you can leave PCF2129 and battery holder out. If

you use the master / slave functionality, the slave clocks don't

require either PCF2129 nor GPS since they will run from internal

PIC oscillator and get synced from master clock every minute. You

can also leave out IR LEDs and their drive components if you don't

need master / slave functionality, or leave out buzzer and drive

components if you don't need alarm / hour beep etc.

The Eagle design files and assembly drawing can be downloaded

below:

kello_hw_v41.zip

9.9.2018 Schematic and board file,

designed with Eagle 5.12. You can order the boards from PCBWay

using this

link.

kello_v41_assy_dwg.pdf

11.9.2018 Assembly drawing including bill of materials

The firmware for the clock is written with CCS PIC-C Compiler. The

source files package including compiled .HEX file are available

for download below.

The IR receiver code was originally based on San

Bergmans's NEC reveiver code and RC-5

receiver code. I have thus simplified them a bit and

converted to C. Also the RC-5 code is improved such that it syncs

the receiver on each received bit. This makes it much more

tolerable to different remotes which may have slightly different

timings. The JVC, Samsung, SIRC, Kaseikyo and Matsushita receiver

codes are written by me but basically they work with same

operating principle (timer interrupt driven state machine). I have

also added auto recognition, so the IR decoder state machine

identifies the code it receives and processes accordingly.

The GPS receiver code is based on code

from CCS customer forums code library posted by PICoHolic.

The code for Bosch BME280 temperature, atmospheric pressure and

relative humidity module comes with the CCS compiler. For PIC16

series of chips, the compiled code can be too big to fit in memory

segments if all code is inline. This can be solved by adding a

#separate directive before int32 _bme280_compensate_H_int32

function. This forces the compiler to realize this function as

separate, not inline, and allows the code to fit in the memory

segments. I also noticed that there was one incorrect register

address in the CCS provided driver, which was causing oversampling

settings not properly set. I have reported this to CCS so it will

probably get fixed in future. The fw v0.91 package below includes

a .diff file which can be used to patch the bme280.c file to fix

this bug and add the #separate directives.

All the rest of the code, including drivers for TLC5925 and

PCF2129 chips is developed by me. You can freely use and modify

them for your own use, but use of them for commercial purposes is

prohibited without written permission from me. You can find

contact info at beginning of the source files or at bottom of this

web page.

Assembling the PCB is quite straightforward. It is best to begin

from bottom side (back side), which has the surface mount

components. The component packages are chosen with DIY in mind,

having comfortably big pin spacing. If you have previous

experience from soldering SMD components, you should be just fine.

As usual, begin from the passive components and then ICs and

transistors.

On top side it is best to solder first other components than

displays and clock colon LEDs. Solder them in order of height,

from lowest to tallest. For the 7-segments displays and LEDs there

are a few tricks to make them look nicer. If you have 7-segment

displays which have black face but white sides, the white sides

are visible even behind a tinted acrylic window. You can use e.g.

black permanent marker or black electrical tape to mask the sides

of the displays. If using permanent marker, it is best done before

soldering the displays. Also, the clock colon LEDs look nicer if

you put shrink tubing around them, so that light only comes out

from top of the LED. It is best to solder the LEDs in place last,

so you can adjust the height to match the 7-segment modules. Below

is an example of LED and display masking.

After successful programming, you should finally see something on

the displays.

Maybe the biggest effort in my clock projects has been the

enclosure. I have used several approaches. I have used the

ready-made Velleman B8009 enclosure with clock versions one and two.

I have built wooden

enclosures and aluminum enclosures with smoke tinted lexan

windows. I have used a photoframe to enclosure the big v4 clock

with 5" seven segment displays. I have designed a sheet metal

enclosure with a sliding acrylic window with mechanical CAD

software. It would be cheap to manufacture in big volumes, but NRE

cost is too high for hobby projects. All these designs serve their

purpose well and even look nice, but they are either labor

intensive or expensive.

Laser cutting has gained popularity, and there are many companies

which offer laser cut services online. In Finland, you can even

use laser cutting machines in some public libraries for free.

PMMA is cheap and cuts nicely with laser. PMMA is also known as

acrylic, or by it's common trade names Plexiglass or Perspex. The

easiest way is to order from some online service, you just supply

the cut files and choose material. I have used Razorlab make the parts

shown in photo below. The material is 3 mm thick opaque black

acrylic for the back panel, and transparent grey tint acrylic for

the front panel. You could also make the back panel from same

transparent material as front panel, as it is a bit cheaper to use

only one material.

I have tested to use transparent red and transparent green PMMA

enclosures as well. The green PMMA form Razorlab has deep green

color (maybe closer to blue than yellow), so it needs displays

with matching pure green color. Many of the green 7-segment

displays are yellowish green, and the brightness is reduced

because of tone mismatch. You can download the design file in SVG

format below:

kello_v4_enclosure_razorlab.svg

Acrylic enclosure design file in .svg format. Designed with

Inkscape.

kello_v4_enclosure_razorlab

- RL1.svg Same design as above, but svg is

optimised by Razorlab. Parallel lines have been joined to reduce

cuts.

Note that if you open the optimized design with

Inkscape, it looks that it is only 75% of the intended size.

This is because it has been edited in Adobe Illustrator. If you

use these files to order from Razorlab, I recommend to mention

that the design has two parts which both are 360x80mm, thus the

whole design is 360x160 mm.

In addition to the acrylic panels, you also need some screws and

spacers. See parts list below.

| Description |

TME part number |

Qty |

| M3x6 button head screw |

B3X6/BN19 for black finish M3X6/ISO7380-1-A2 for natural finish |

16 |

| M3x8mm spacers with internal thread | TFF-M3X8/DR124 | 8 |

| M3x12mm spacer screws with internal and external threads | B3X12/BN3318 | 4 |

| M3 plain washer |

B3/BN1414 | 4 |

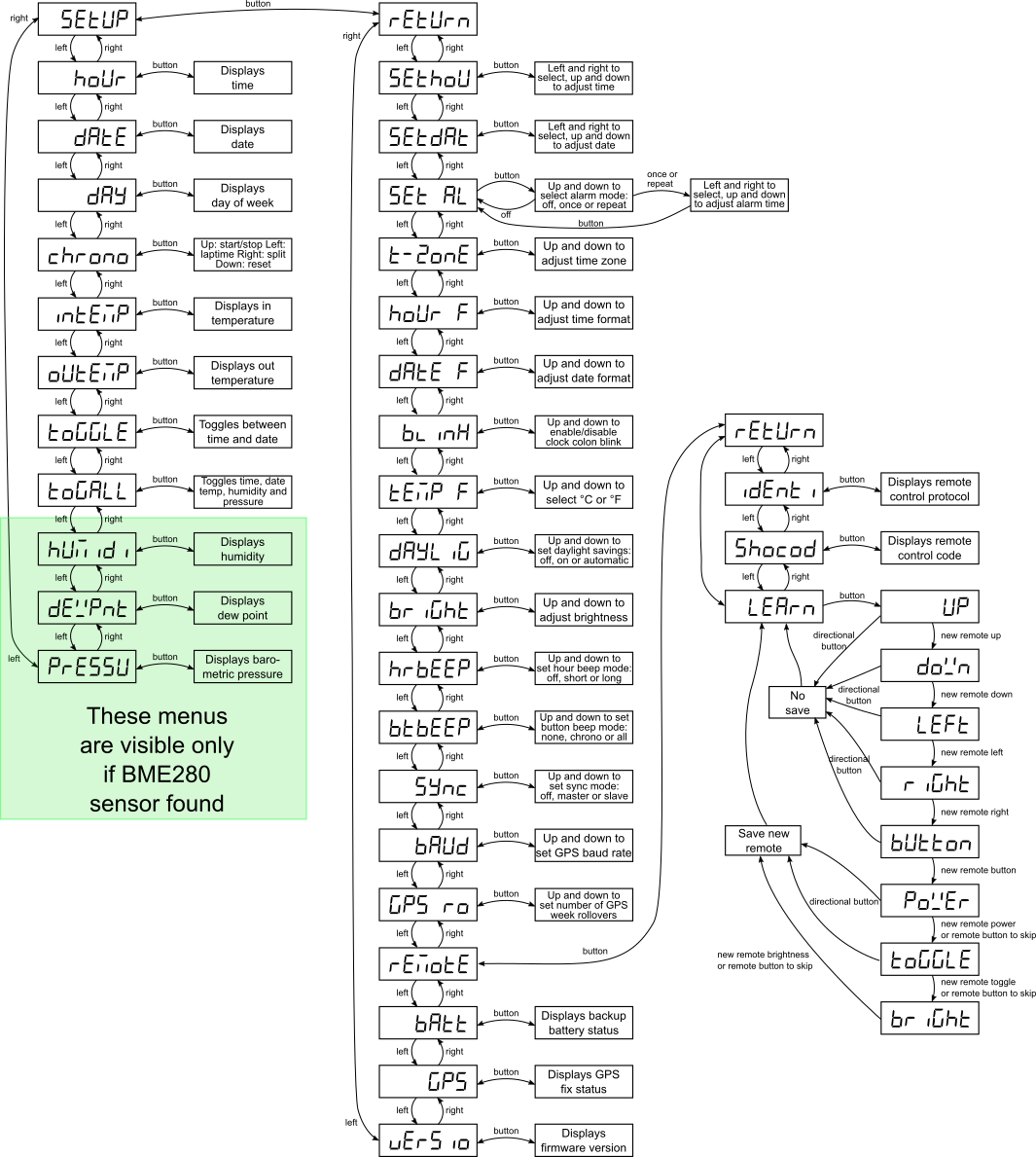

The firmware implements a menu system which allows to select a

desired display mode and also to setup the various configurable

functions. You can move in the menu system using the 5-way

directional switch on the PCB or with an IR remote control. Below

is diagram of the menu structure as it is in firmware v1.22. Click

the image to download it as PDF.

When you have succesfully programmed the clock, it's time to

setup it. First you probably want to teach the clock your remote

control. If not, you can skip to next chapter. Use the 5-way

directional switch to navigate to setup menu, and from there to

remote menu. You can use the diagram above as guidance. It's best

first to test your remote whether is uses a coding which the clock

supports. Go to 'identify' display which shows the IR remote

control protocol, if it is identified. Press your remote control

buttons. The following codings are currently supported:

If you are unlucky, the display shows 'Error', which means that

the remote control coding is not recognized. Try to find another

remote. If display stays at 'nonE', it might be that your remote

is not an IR remote at all, or more likely, has dead batteries.

Try if using fresh batteries help. Nearly empty batteries can also

sometimes be reason to get 'Error', if the remote signal is too

weak to be properly recognized.

When you have identified a remote which is recognized by the

clock, you can teach it. Navigate to 'LEArn' in remote menu. The

clock will display the eight button names one after another. 'UP',

'doWn', 'LEFt', 'riGht', 'bUtton', 'PoWEr', 'toGGLE' and 'briGht'.

Press a desired key in your remote to teach it. If your remote

doesn't work here for some reason and you can't proceed, you can

exit learn mode by pressing 5-way directional button. The last

three buttons aren't mandatory. You can press here same remote

button as you used for 'bUtton' to skip those optional buttons you

don't want to program. You can also press 5-way directional

switch, which skips all optional buttons and saves just the five

compulsory ones.

Now you should have a working remote control. If there is a

problem, try to learn it again. If it doesn't help, you can go to

'Shocod' which will display the remote control address and command

for each remote control button. The first four digits show address

in hexadecimal. The last two digits show the command. Ensure that

all the buttons you are going to use transmit the same address, as

this is what the clock expects.

There are already three possible time sources for the clock; the PCF2129 RTC, the U-Blox GPS module and time reception from master clock via IR messages. The PCF2129 RTC is very accurate and enough in most cases.

The U-Blox GPS module is quite expensive, and in many cases a bit

overkill. The GPS reception can also be problematic indoors.

One alternative is to use internet time from NTP timeserver. I was

thinking of implementing a NTP to GPS time bridge using ESP8266.

Fortunately I did a web search first, and found this excellent fakeGPS project

by SnowHead which does exactly that. I had to make some changes to

the code. This modified code sends

time as GPRMC message each second, just like the U-Blox GPS

module. I've also changed it to send the 'A' or 'V' which in GPRMC

message indicates whether GPS has fix. If the ESP8266 hasn't been

able to udpate time from NTP server within the last hour, it will

indicate this as 'no fix'. This prevents the clock from saving

possibly inaccurate time to RTC. I recommend to use the v1.20 or

later firmware for clock, as there are some changes to improve

operation with fakeGPS.

See the fakeGPS github page for required libraries and setup etc.

I have left the daylight savings time code into the sketch. But at

least in Europe you don't need to make any changes in the code. It

is by default set to GMT, as GPS time always is. You just need to

set the timezone and daylight savings time in clock setup menu. If

your country has different dst rules, you can enter them into the

sketch before compiling.

I have tested the fakeGPS with NodeMCU and ESP-01. Both work OK.

With ESP-01, remember that you must connect EN pin (6) to 3v3 pin

(8). You'll need 3 wires for connection to clock:

The ESP current draw when WiFi transmission is active could be a

bit high for the SOT223 case regulator. But in practice it seems

to run OK, as the amount of WiFi transfers is small. You can also

use separate power supply for the ESP module, and only connect GND

and TX to clock.

page created 25.12.2017

last updated 20.7.2025 webmaster@kair.us

kair.us/ projects/ seven segment wall clocks/ kello version 4