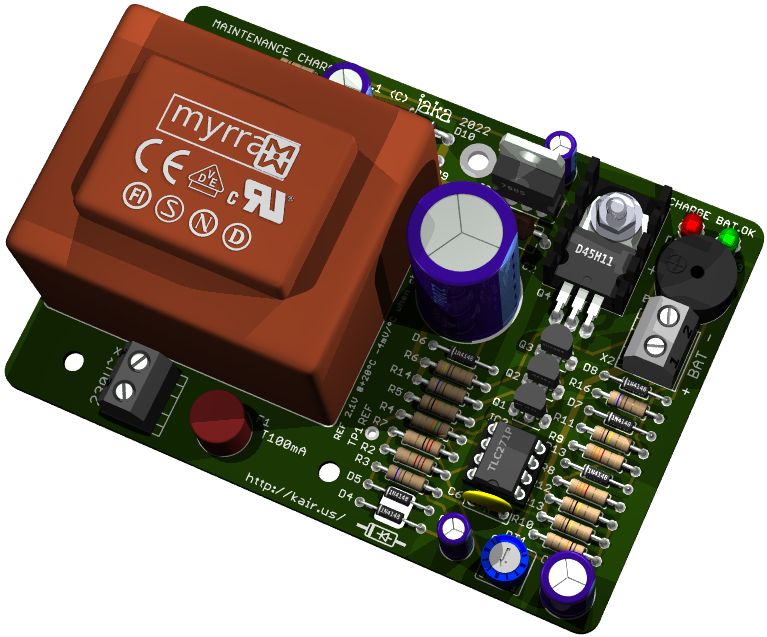

On this page you find all the information needed to build a

maintenance charger for lead-acid batteries. It has protection

against short circuit and reverse connection. The charger has

automatic temperature compensation, unlike most of the popular

CTEK chargers.

One method of maintenance charging is float charging. This means

that the charger produces constant voltage, e.g. 13.8 V, which is

continuously applied to the battery. This means that the battery

is constantly full. At least in theory, this could cause some

unwanted boiling in battery.

This charger stops charging when the battery voltage reaches 13.8

V. The charging starts when voltage drops to 12.6 V. This ensures

that battery is always full enough to prevent from freezing and

sulphation. These voltage switchpoints are temperature

compensated. In 0ºC, the switchpoints are and 14.3 and 13.1 V.

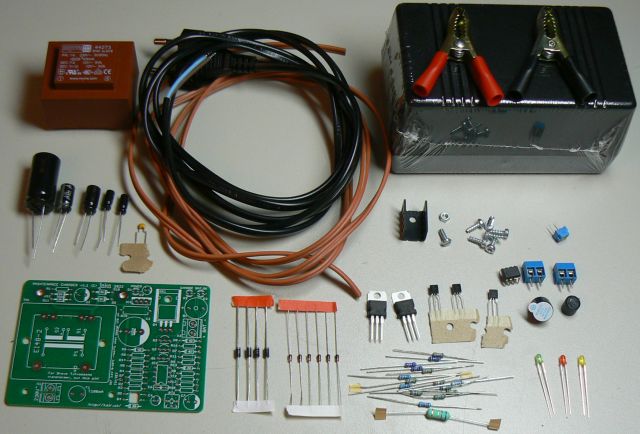

The parts of TME shared project are shown below (M3 screw and nut for TO220 heatsink fixing are not included in in shared project)

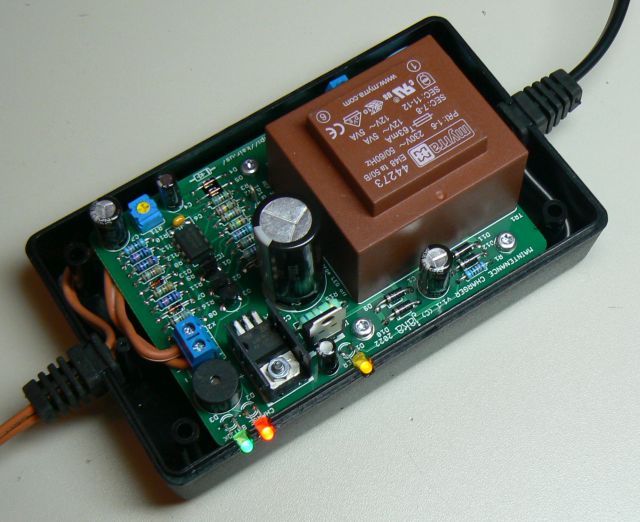

Assembly of the unit is straightforward. The heatsink for transistor doesn't need to be isolated. Leave LED legs long enough, so the LEDs can be bent to side seam of enclosure.

The Myrra transformer can be fixed to PCB with two 3 x 8 mm

plastic screws. The same screws are required to fix the PCB to

enclosure. The enclosure only includes the screws needed to close

the enclosure. Circuit diagram lists alternative PCB transformers

from different manufacturers, but only the Myrra brand has the

screw holes. The other types are held in place only by solder

joints.

You can route the cables around the posts for added strain

relief. The brown cable is LAPP 0065202,

2x0,75mm2

with silicone insulation. It stays flexible in cold, but the

insulation is easy to tear at sharp edges. It is so soft that you

can strip it with your nails. The PVC mains cable becomes very

stiff when cold.

Before use, the voltage threshold needs to be adjusted. Measure

voltage from TP1, and adjust with RT1. Set the voltage to 2.1 V

when charge LED does not light. If ambient temperature is other

than +20ºC, compensate this reading -4 mV/ºC. For example, if the

adjustment is done at 0ºC, adjust TP1 voltage to 2.18 V. The

adjustment is easier if you connect the charger to a full battery,

or if you connect big enough capacitor to output terminals.

Otherwise, the charge LED is off only very briefly. The adjustment

procedure is described on schematic diagram and on bottom of the

board as well. Another tip is to keep the charger powered for some

time, with enclosure closed, before adjustment. This takes the

self heating of charger into account.

Using the charger is simple. Connect the charger to battery.

Ensure that the green 'BATTERY OK' LED lights. Then connect mains

cable. Ensure that yellow 'POWER' LED lights. All set! The red

'CHARGE' LED indicates that the battery is being charged.

If you are visiting the location where battery/vehicle is stored,

it is worth checking that both yellow and green LEDs are

constantly lit. It indicates that all is OK. If the yellow LED is

off, the charger is not getting power. If the green LED is

flashing, it indicates that connection to battery is not good.